Visit our cellar, with its 120 hundred-year-old oak foudres. These veritable monuments of the cellar are equipped with a thermoregulation system and symbolise the perfect synthesis of tradition and innovation.

When it’s time to harvest, we pick the grapes when they are ripe and transport them in less than 2 hours by conquest to reduce handling. Once in the cellar, the grapes are gently pressed in our latest-generation pneumatic presses. Apart from the Pinot Noir, the grapes are not destemmed!

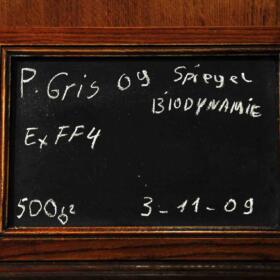

Slow, regular pneumatic pressing produces almost crystal-clear juice. The juice is clarified by static settling. The perfectly clear juice is left to ferment at a controlled temperature of between 20°C and 23°C in century-old oak foudres for 6 to 12 weeks.

The new wine is then racked and rested for 8 to 9 months on fine lees in tuns. To produce our cuvées, 80 temperature-controlled stainless steel vats are installed for a strict parcel-by-parcel selection. In this way, the freshness and fruit are fully preserved.

The wine is then matured at a constant temperature for 12 to 18 months in a stainless steel vat, before being prepared for bottling.

The wines are then bottled on site using a bottling line equipped with electro-pneumatic nozzles that inject nitrogen: this considerably reduces the addition of SO2 (sulphites) to the wines, while preserving their aromatic richness and brilliant colour.

All our wine bottles are corked with natural cork, selected by us. We have been working hand in hand with the same suppliers for over 50 years.

The bottled wine, stored in pallet boxes, is kept in our cellars for several months, before being labelled and then shipped around the world.

All our work in the cellar is checked by ECOCERT once a year. The traceability of our wines is checked from the vine to bottling.